Navigating the Future of Logistics Technology

Role in Modern Logistics and Supply Chains

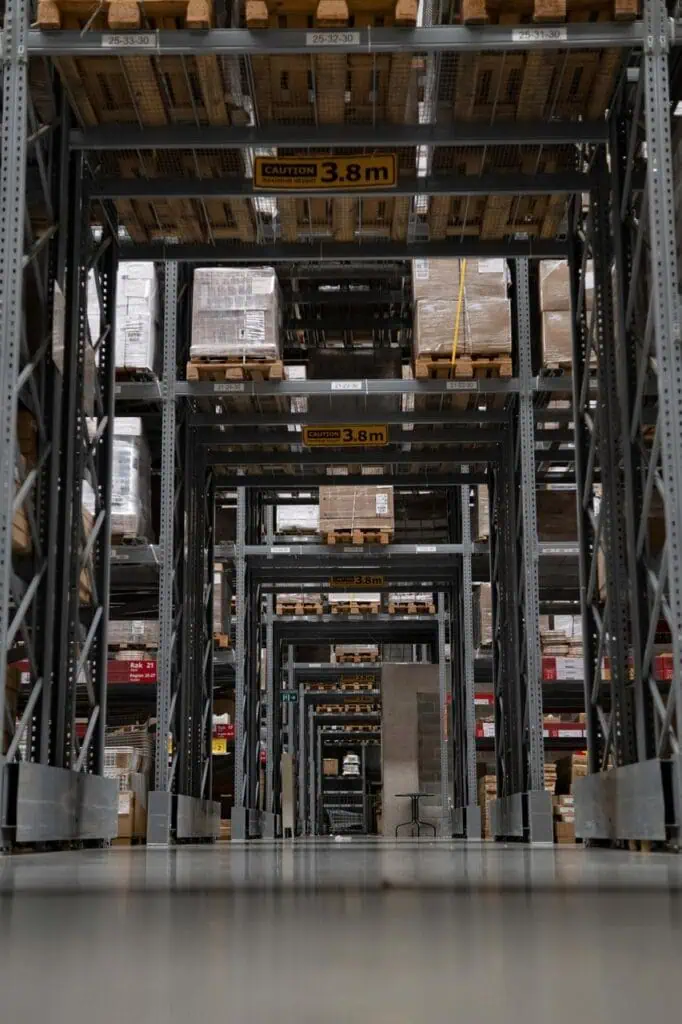

The automated warehouse systems operator profession represents a cutting-edge and rapidly growing role in modern logistics, focusing on the operation, monitoring, and troubleshooting of advanced robotics and AI-driven systems that power today’s smart distribution centers.

As supply chains increasingly embrace automation to meet growing e-commerce demands, automated warehouse systems operator jobs provide exciting career opportunities at the intersection of technology and logistics.

Modern automated warehouse operators work in technologically sophisticated environments—from high-volume e-commerce fulfillment centers and retail distribution facilities to third-party logistics providers and manufacturing warehouses utilizing advanced automation. This role is part of our Transportation, Warehousing & Distribution Service Career series.

This comprehensive guide explores the evolving responsibilities of warehouse automation specialists, detailing the technical skills, certifications, and experience needed to succeed in this dynamic field while highlighting pathways for career advancement and specialization opportunities in logistics technology.

Warehouse Automation Industry Overview

The global demand for qualified automated warehouse systems operators continues to grow exponentially as companies invest heavily in robotics, artificial intelligence, and automated systems to enhance logistics efficiency and meet accelerating customer delivery expectations. Today’s automated warehouse operators are essential specialists managing sophisticated technologies in e-commerce fulfillment centers, retail distribution hubs, third-party logistics providers, and manufacturing facilities. The profession stands at the convergence of logistics operations, robotics management, and information technology.

Several key trends are reshaping automated warehouse operations job market conditions:

- Robotics deployment is accelerating rapidly, with automated storage and retrieval systems (AS/RS), autonomous mobile robots (AMRs), and robotic picking systems becoming standard in modern warehouses

- Artificial intelligence and machine learning are enhancing predictive maintenance, inventory optimization, and automated decision-making throughout warehouse operations

- Cloud-based warehouse management systems (WMS) have transformed how operators interact with and control automated equipment

- Labor shortages and rising wages are driving increased investment in automation technologies, creating demand for skilled operators

- The Internet of Things (IoT) is enabling unprecedented connectivity between warehouse systems, requiring operators with integrated technical knowledge

The field also faces important operational considerations, including cybersecurity for automated systems, integration between legacy and new technologies, and maintaining operational continuity during technological transitions. As logistics automation continues to advance, warehouse automation specialists with both technical aptitude and operational understanding remain in exceptionally high demand across virtually all sectors handling physical goods.

Warehouse Robotics Specialist Jobs

Automated warehouse systems operator positions offer excellent employment prospects worldwide, with particularly robust demand in these sectors:

- E-commerce Fulfillment Centers: High-volume operations utilizing extensive automation to meet rapid shipping requirements

- Retail Distribution Hubs: Regional and national distribution centers implementing robotics to support omnichannel retail

- Third-Party Logistics (3PL) Providers: Contract logistics operations investing in automation to increase efficiency and service capabilities

- Manufacturing and Production Facilities: Factories implementing automated material handling and inventory management systems

- Grocery and Food Distribution: Temperature-controlled automated warehouses supporting food retail and delivery services

Popular regions for automated warehouse systems operator jobs include:

- North America: Strong demand across the USA and Canada, particularly near major e-commerce fulfillment hubs and technology centers

- Europe: Excellent opportunities in Germany, the Netherlands, the UK, and France, where automation adoption is advanced

- Asia-Pacific: Rapidly expanding opportunities in Japan, South Korea, Singapore, and China’s major logistics centers

- Australia/New Zealand: Growing market with sophisticated logistics networks implementing advanced automation

- Middle East: Emerging opportunities in UAE and Saudi Arabia as new automated distribution centers are established

Most positions require technical training in automation systems, understanding of warehouse management software, and increasingly, knowledge of programming or data analysis. Advanced roles often require specialized certifications in robotics operation, automation technologies, or specific vendor platforms.

Average Automated Warehouse Systems Operator Salary Comparison (Annual)

Region Entry-Level Mid-Level Senior/Specialist

USA $45,000-$60,000 $60,000-$80,000 $80,000-$110,000+

UK £35,000-£45,000 £45,000-£60,000 £60,000-£80,000+

Canada CAD CAD CAD $85,000-$110,000+ $50,000-$65,000 $65,000-$85,000

Australia AUD AUD AUD $90,000-$120,000+ $55,000-$70,000 $70,000-$90,000

New Zealand NZD NZD NZD $75,000-$95,000+ $50,000-$65,000 $65,000-$80,000

Europe €40,000-€55,000 €55,000-€70,000 €70,000-€90,000+

Asia $25,000-$40,000 $40,000-$60,000 $60,000-$85,000+

Operators with specialized expertise in specific automation platforms, robotics programming, or AI-integration typically command premium salaries. Additionally, many companies offer performance-based bonuses tied to system uptime, throughput metrics, and successful automation implementation projects.

Warehouse Automation Career Potential Grade: ⭐⭐⭐⭐⭐ (Excellent)

The career potential for automated warehouse systems operators is exceptionally strong, particularly in these areas:

- Robotics Implementation and Integration: Tremendous opportunities in deploying and optimizing new warehouse automation systems

- AI and Machine Learning Applications: Growing roles in implementing artificial intelligence for predictive warehouse operations

- Automation Maintenance Engineering: Advanced positions in ensuring continuity and performance of complex robotic systems

- Warehouse Technology Management: Leadership roles overseeing complete technological ecosystems in distribution centers

- Automation Consulting and Solution Design: Advisory positions helping companies design and implement warehouse automation strategies

Career advancement typically depends on continuous technical education, hands-on experience with multiple automation platforms, and increasingly, software and data analysis capabilities that bridge operational technology with information technology.

Key Automated Warehouse Systems Operation Skills & Requirements

Technical Operations Skills

- Robotics Management: Proficiency operating automated storage and retrieval systems (AS/RS), autonomous mobile robots (AMRs), and robotic picking systems

- System Monitoring: Ability to monitor automated system performance, identify anomalies, and evaluate operational metrics

- Troubleshooting & Problem Resolution: Skills in diagnosing automated system malfunctions, implementing solutions, and restoring operations

- Software Interface Operation: Expertise with warehouse management systems (WMS) and warehouse execution systems (WES) that control automation

- Maintenance Coordination: Knowledge of preventive maintenance schedules and ability to coordinate with technical specialists for repairs

Advanced Technical Knowledge

- Automation Integration Understanding: Comprehension of how different automated systems interact within the warehouse ecosystem

- Basic Programming Concepts: Familiarity with programming logic, data structures, and simple scripting for automation systems

- Warehouse Database Management: Skills in data entry, validation, and basic database queries for inventory and operational data

- IoT and Sensor Technology: Understanding of connected devices and sensor networks that support automated operations

- Machine Learning Applications: Knowledge of how AI applications enhance automated decision-making in warehouse operations

Safety & Compliance Requirements

- Robotic Safety Protocols: Thorough understanding of safety zones, lockout procedures, and emergency stops for automated systems

- Cybersecurity Awareness: Knowledge of digital security risks and procedures for automated control systems

- Regulatory Compliance: Familiarity with standards governing automated equipment and material handling systems

- Risk Assessment: Ability to identify potential safety hazards in human-robot collaborative environments

Professional Qualifications

- Formal Education: Typically requires minimum associate degree in logistics technology, mechatronics, or related field, with bachelor’s degrees increasingly preferred for advancement

- Essential Certifications: Industry-recognized credentials such as Certified Automated Warehouse Technician, Robotics Operations Specialist, or vendor-specific platform certifications

- Experience Requirements: Generally 1-3 years of warehouse experience before specializing in automation, with demonstrated technical aptitude

Professional Attributes

- Analytical Thinking: Methodical approach to system optimization and problem-solving

- Technical Adaptability: Ability to quickly learn new technologies and platforms as automation evolves

- Attention to Detail: Precision in monitoring system parameters and identifying potential issues

- Communication Skills: Ability to translate technical concepts for non-technical colleagues

- Calm Under Pressure: Capability to manage system disruptions while maintaining operational flow

Professionals who combine practical warehouse operational knowledge with technical understanding of automation systems are particularly well-positioned for career advancement in this rapidly evolving field.

Warehouse Automation Career Paths: From Operator to Technology Leader

Entry-Level Automated Warehouse Positions

Automated Systems Associate

- Learning basic operation of warehouse automation equipment

- Monitoring automated processes and system performance

- Reporting anomalies and basic troubleshooting under supervision

- Starting salary range: $45,000-$55,000

Inventory Control Technician

- Managing inventory data within automated storage systems

- Reconciling physical and system inventory discrepancies

- Ensuring accurate data for automated picking and putaway

- Starting salary range: $48,000-$58,000

Warehouse Automation Assistant

- Supporting operation of specific automated subsystems

- Helping with routine maintenance and system checks

- Learning workflow optimization in automated environments

- Starting salary range: $50,000-$60,000

Mid-Level Warehouse Technology Careers

Certified Automated Warehouse Systems Operator

- Independently operating multiple automated systems and robots

- Troubleshooting and resolving common technical issues

- Optimizing automated workflows for maximum efficiency

- Average salary range: $60,000-$75,000

Robotics Integration Specialist

- Configuring and implementing robotic systems for specific tasks

- Managing interface between automated and manual operations

- Customizing robotics for specific warehouse requirements

- Average salary range: $65,000-$80,000

Automation Performance Analyst

- Analyzing data from automated systems to identify improvements

- Implementing optimizations to increase throughput and accuracy

- Developing KPIs and performance reporting for automated operations

- Average salary range: $70,000-$85,000

Senior-Level Warehouse Automation Positions

Warehouse Automation Manager

- Overseeing complete automated systems within a facility

- Managing teams of automation operators and technicians

- Developing strategies for automation optimization and expansion

- Average salary range: $80,000-$100,000

Robotics Operations Supervisor

- Directing robotic fleet management and optimization

- Implementing advanced programming and customization

- Coordinating with vendors on system upgrades and enhancements

- Average salary range: $85,000-$105,000

Warehouse Technology Solutions Specialist

- Integrating multiple automation technologies for cohesive operations

- Leading implementation of new automated systems

- Developing strategies for legacy system migration and upgrade paths

- Average salary range: $90,000-$110,000

Advanced Logistics Technology Leadership Opportunities

Director of Warehouse Automation

- Strategic leadership of automation across multiple facilities

- Budget responsibility for technology investment and ROI

- Long-term automation roadmap development and implementation

- Average salary range: $110,000-$140,000+

VP of Supply Chain Technology

- Executive oversight of all logistics technology initiatives

- Integration of warehouse automation with broader supply chain systems

- Vendor relationship management and technology partnership development

- Average salary range: $130,000-$180,000+

Chief Automation Officer

- C-level responsibility for enterprise-wide automation strategy

- Cross-functional leadership connecting IT, operations, and engineering

- Strategic alignment of automation with overall business objectives

- Average salary range: $150,000-$200,000+

Many automated warehouse systems operators find their career path evolves from operational roles to more technical and strategic positions. The transition from manual warehouse operations to automation represents a pivotal career opportunity as the industry continues its technological transformation, opening doors to numerous advancement possibilities for those who develop both technical skills and operational expertise.

Automated Warehouse Operator Resume Tips

Crafting a compelling automated warehouse systems operator resume requires highlighting both technical proficiency with automation systems and practical understanding of warehouse operations. The best resume format for automated warehouse systems operators emphasizes specific technology platforms, problem-solving capabilities, and continuous learning in this rapidly evolving field.

Essential Automated Warehouse Resume Sections

Professional Summary

- Concise overview of automation experience, technical capabilities, and operational understanding

- Example: “Certified Automated Warehouse Systems Operator with 4+ years of experience managing robotic picking systems and autonomous mobile robots in high-volume e-commerce fulfillment operations. Skilled in WMS software operation, predictive maintenance, and automation troubleshooting, with a track record of maintaining 99.2% system uptime while implementing process improvements that increased throughput by 22%.”

Technical Skills

- Specific automation platforms and robotics systems (AS/RS, AMR, robotic arms)

- Software proficiencies (WMS systems, control interfaces, database tools)

- Technical competencies (system monitoring, troubleshooting, optimization)

Automation Projects & Achievements

- Specific examples of system implementations, optimizations, or problem resolutions

- Quantify results with percentages, throughput metrics, or uptime statistics

- Highlight innovative approaches to automation challenges

Work Experience

- Detailed but concise descriptions of automation responsibilities and achievements

- Focus on technical problem-solving, system optimization, and operational improvements

- Highlight experience with specific industries or specialized warehouse environments

Certifications & Technical Education

- Industry-recognized credentials (automated systems, robotics, specific platforms)

- Formal education in logistics technology, mechatronics, or related fields

- Continuing education in emerging warehouse technologies

Warehouse Automation Resume Formatting Tips

- Use technical language that demonstrates familiarity with automation systems

- Include specific metrics that showcase your impact (e.g., “Reduced system downtime by 35% through implementation of predictive maintenance monitoring” or “Optimized AMR routing algorithms resulting in 18% increase in picking efficiency”)

- Highlight experience with specific automation brands and platforms that match employer requirements

- Balance technical skills with operational understanding to demonstrate comprehensive capabilities

When applying for automated warehouse positions, pair your resume with a targeted cover letter that connects your specific experience to the automation technologies used by the prospective employer. Many applicants benefit from using a resume builder or cv maker that offers templates optimized for technical positions, ensuring all crucial information is presented effectively.

For those seeking to transition from traditional warehouse operations to automation roles, emphasize technical aptitude, any experience with warehouse management systems, and your adaptability to new technologies to demonstrate your readiness for this evolving career path.

Warehouse Robotics Interview Questions: Preparation for Technical Assessments

The interview process for automated warehouse systems operator positions typically combines operational questions with specific assessments of technical knowledge and problem-solving capabilities. Employers evaluate both system understanding and practical troubleshooting abilities through targeted questioning.

Common Automated Warehouse Systems Operator Interview Questions and Response Strategies

Technical System Knowledge

- “Describe your experience with automated storage and retrieval systems (AS/RS).”

- Discuss specific platforms or brands you’ve operated

- Explain your role in monitoring, optimizing, and troubleshooting

- Demonstrate understanding of key performance metrics and operational parameters

- “How would you respond to an autonomous mobile robot (AMR) navigation failure in a busy warehouse environment?”

- Outline systematic troubleshooting approach for navigation issues

- Explain safety protocols during robot recovery operations

- Discuss temporary workflow adjustments to maintain productivity

Operational Problem-Solving

- “Describe a situation where you improved the efficiency of an automated warehouse system.”

- Structure response to show problem identification, solution approach, and quantifiable results

- Highlight collaborative aspects involving technical teams or vendors

- Demonstrate understanding of both technical and operational impact

- “How would you manage a major system failure during peak volume period?”

- Detail contingency planning and failover procedures

- Explain prioritization of critical workflows and recovery steps

- Discuss communication protocols with management and technical support

Integration and Collaboration

- “How do you coordinate with maintenance technicians when automated systems require repairs?”

- Describe documentation and communication processes

- Explain how you help diagnose issues to expedite repairs

- Discuss workflow adjustments during maintenance periods

- “How do you train new team members on automated warehouse systems?”

- Outline structured training approaches for different learning styles

- Explain how you balance technical concepts with practical operation

- Discuss safety emphasis and error prevention strategies

Technical Adaptability and Learning

- “How do you stay current with emerging warehouse automation technologies?”

- Describe continuous learning strategies and resources

- Highlight specific new technologies you’ve recently mastered

- Demonstrate enthusiasm for technological advancement

- “What automation platforms or systems are you most interested in learning more about?”

- Research employer’s current and planned automation systems before interview

- Show informed interest in relevant technologies

- Connect learning interests to operational improvements

Automated Warehouse Interview Preparation Tips

- Review System Technical Specifications

- Refresh knowledge of automation systems you’ve worked with

- Research platforms used by the prospective employer

- Be prepared to discuss technical details and operational parameters

- Prepare Troubleshooting Scenarios

- Develop examples of common system failures and your resolution approaches

- Practice explaining technical issues in clear, concise language

- Consider how to describe complex problems to both technical and non-technical listeners

- Research Current Automation Trends

- Update knowledge on emerging technologies in warehouse automation

- Understand how AI and machine learning are enhancing warehouse operations

- Identify how IoT and connectivity are improving system integration

- Develop Questions About Their Automation Environment

- Prepare thoughtful questions about their specific systems and challenges

- Ask about planned technology investments or upgrades

- Inquire about how automation integrates with their broader operation

Successful automated warehouse systems operator interviews require balancing technical knowledge with practical operational understanding. Employers seek candidates who can both optimize complex systems and collaborate effectively with various teams to maintain productive warehouse operations. Highlighting your problem-solving approach to automation challenges and continuous learning mindset will strengthen your candidacy for these highly sought-after positions.

Global Warehouse Automation Career Opportunities: Regional Market Comparison

The global logistics and distribution industry offers diverse opportunities for automated warehouse systems operators, with significant variations in technology implementation, compensation, and career advancement potential across different regions. Understanding these market differences helps technology specialists identify the most promising career locations.

Top Countries for Warehouse Automation Employment

United States

- Leader in e-commerce fulfillment automation and advanced robotics implementations

- Strong demand in technology corridors and major logistics hubs

- Significant investment in next-generation warehouse technologies

- Higher than average compensation for specialized platform expertise

Germany

- Engineering excellence creating sophisticated automation solutions

- Strong manufacturing sector with advanced material handling systems

- Leaders in Industry 4.0 implementation and warehouse connectivity

- Excellent technical training and certification pathways

Japan

- Pioneer in warehouse robotics and automation technology

- High density of advanced automated distribution centers

- Significant investment in AI-enhanced logistics solutions

- Strong emphasis on continuous process improvement

Netherlands

- Strategic European logistics hub with advanced automation

- High concentration of sophisticated distribution centers

- Strong focus on sustainable automation solutions

- Excellent work-life balance compared to other markets

Singapore

- Leading Asian hub for implementing cutting-edge automation

- Strategic investment in developing automation expertise

- High-density operations driving innovative solutions

- Strong government support for logistics technology development

Regional Warehouse Automation Career Considerations

Technology Implementation Variations

- Automation adoption rates vary significantly between regions

- Some markets utilize more advanced systems while others are still transitioning

- Consider alignment with your technology interests and experience

Technical Training and Certification Differences

- Educational pathways and certification recognition vary by region

- Some markets have standardized automation credentials

- Consider transferability of qualifications between countries

Industry Focus and Automation Applications

- Regions differ in primary sector applications (retail, manufacturing, etc.)

- Some markets emphasize specific automation technologies

- Consider specialization opportunities in various markets

Work Culture and Innovation Approach

- Approaches to technology implementation vary culturally

- Decision-making processes and change management differ

- Consider alignment with your preferred working style

Many automated warehouse systems operators build global careers by gaining experience with major technology providers or multinational logistics companies. While core automation principles remain consistent globally, implementation approaches, technology preferences, and career advancement structures can vary dramatically based on region and company.

Conclusion: Building Your Warehouse Automation Technology Career

The automated warehouse systems operator profession represents one of the most dynamic and promising career paths in modern logistics, combining technical expertise with operational knowledge at the forefront of supply chain innovation. As warehouse automation continues its rapid advancement, skilled professionals who can effectively operate, optimize, and troubleshoot these complex systems remain in exceptionally high demand across virtually all industries handling physical goods.

To maximize your potential in this transformative field:

- Pursue specialized certifications in specific automation platforms and robotics systems

- Develop a balance of technical knowledge and practical warehouse operational understanding

- Build experience across multiple automation technologies to enhance versatility and value

- Cultivate problem-solving capabilities focused on maintaining operational continuity

- Embrace continuous learning as automation technologies evolve rapidly

Whether you’re drafting your first application letter for an entry-level position or advancing toward a technical leadership role, approach your warehouse automation career with both technological curiosity and operational pragmatism. The field rewards those who can effectively bridge the gap between advanced technology and practical logistics requirements.

Use the resources at CV4Students to create a professionally structured automated warehouse systems operator resume that showcases your technical capabilities and problem-solving achievements. With the right preparation and dedication to continuous technical education, you can build an exceptionally rewarding career path at the forefront of logistics technology that offers substantial advancement opportunities as automation continues transforming global supply chains.

Explore More in This Industry

Looking for other career options in this field?

👉 View more Transportation, Warehousing & Distribution Service Careers.

Resources & Organizations

These featured organizations play an active role in advancing pest management, scientific research, and agricultural development through education, policy, and innovation.

The African Association of Insect Scientists (AAIS) is a professional body committed to strengthening entomological science across Africa through research, education, and pest management innovation.

Visit Site →

The New Zealand Plant Protection Society promotes the science and practice of plant protection through conferences, publications, and collaboration with growers, researchers, and pest control professionals.

Visit Site →

The Agricultural Research Council of South Africa – Plant Protection leads national research efforts in crop protection, biosecurity, pest diagnostics, and integrated pest management (IPM) for sustainable agriculture.

Visit Site →

These organizations are featured for their outstanding contributions to pest management science, training, and global agricultural development.

This Automated Warehouse Systems Operator Career Guide provides general information about the profession globally. Specific requirements, compensation, and opportunities may vary by region, employer type, and individual qualifications. Always research current conditions in your target market when making career decisions.